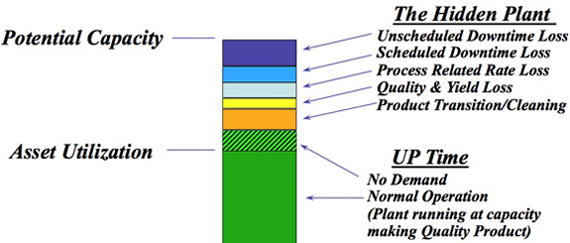

| Operational Optimization & Stability: Our Asset Utilization Process helps to use an integrated approach to target and quantify improvement opportunities. |

1. Increased throughput equals increased profit

2. Consistent measure across entire business

3. Clear indicator of actual use of the businesses assets

4. Ability to track actual improvements in productivity

5. Identifies where to best apply the business’ precious resources

80% of potential clients cannot quantify the business value of Their Hidden Plant |

|

| Asset Utilization: Designed to Focus Opportunities for Improvement |

|

Many potential clients have not focused resources on their process constraint

Improvement Work Process

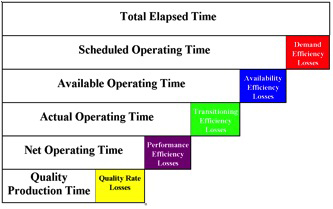

• Rigorous System to Record ALL Operational Losses in a Set of Fixed Categories and Sub-Categories.

• Data to be entered by the Technician Level and/or input directly from the Process Control System.

• Entries have enough detail to enable holistic Root Cause Analysis.

• “Cost of Lost Production” data is used to determine Return on Investment for Improvement Efforts.

The Tool

• Data-base program configured for the Asset Utilization Work Process.

• Reconciles Operational Losses appropriately to determine Operational Efficiencies.

• Adapted for simplified technician input and/or automatic data entry.

• Standardized approach for all Operating Units within the Business Unit. |

Back to the top |

| |